Products Description

Brief Introduction

Stainless steel silos/hoppers are storage equipment in the mechanized handling system for bulk materials, mainly functioning as intermediate storage, system buffering, and balanced operation. A silo/hopper device consists of a silo/hopper, as well as components such as feeding and discharging parts.

It is suitable for the transfer of materials in closed production processes in pharmaceutical enterprises, food enterprises, chemical enterprises, and other related industries. The top cover and valves of this equipment are all equipped with silicone sealing rings, ensuring that medicines are stored in a closed, safe, and moisture-proof manner. Materials can fulfill different purposes in the same container, eliminating frequent processes such as material transfer and refeeding, and effectively preventing cross-contamination from dust. It fully complies with the GMP requirements for pharmaceutical and food production.

Features

The silo/hopper is made of high-quality 304 or 316L stainless steel through refined manufacturing.

The external shape is either a square silo/hopper with rounded corners and a conical bottom or a circular silo/hopper. All corners adopt arc transitions, ensuring no dead ends, no material residue, and an aesthetic appearance.

Both the inner and outer surfaces undergo high-precision polishing treatment. The surface roughness of the inner surface can reach Ra ≤ 0.2μm, and that of the outer surface can reach Ra ≤ 0.8μm.

The specially designed hopper cover and butterfly valve are both equipped with silicone sealing devices to ensure sealing performance.

All welding joints are processed with groove preparation; after double-sided TIG (Tungsten Inert Gas) welding, they are ground and polished. The welding quality complies with the requirements of JB4708 and JB4709.

It is equipped with specially made casters to protect the ground in clean areas from damage and avoid leaving marks.

The silo/hopper has sufficient strength and no deformation occurs.

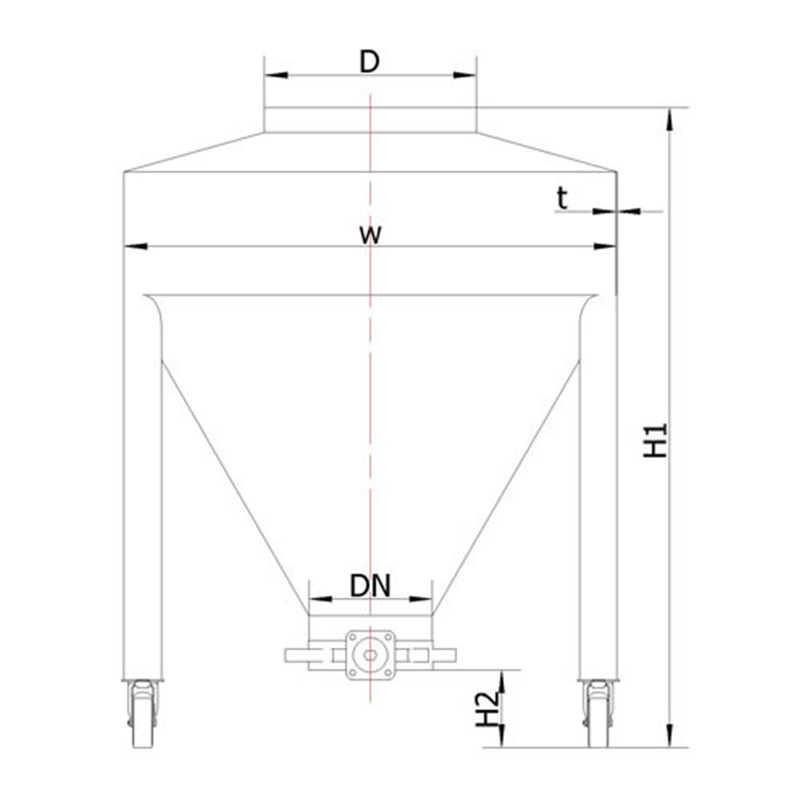

Parameters

| Model | Specification (mm) | Volume | Thickness | ||||||

| H1 | H2 | W | D | DN | L | t | |||

| LDF-200 | 1097 | 158 | 594 | 100 | 150 | 200 | 2.5 | ||

| LDF-300 | 1168 | 204 | 794 | 125 | 200 | 300 | 2.5 | ||

| LDF-400 | 1290 | 165 | 794 | 125 | 200 | 400 | 2.5 | ||

| LDF-500 | 1331 | 229 | 994 | 125 | 200 | 500 | 2.5 | ||

| LDF-600 | 1366 | 151 | 994 | 125 | 200 | 600 | 2.5 | ||

| LDF-800 | 1545 | 118 | 994 | 125 | 200 | 800 | 2.5 | ||

| LDF-1000 | 1586 | 168 | 1194 | 150 | 250 | 1000 | 2.5 | ||

| LDF-1500 | 1868 | 99 | 1194 | 150 | 250 | 1500 | 3 | ||

| LDF-2000 | 2238 | 113 | 1194 | 150 | 250 | 2000 | 3 | ||

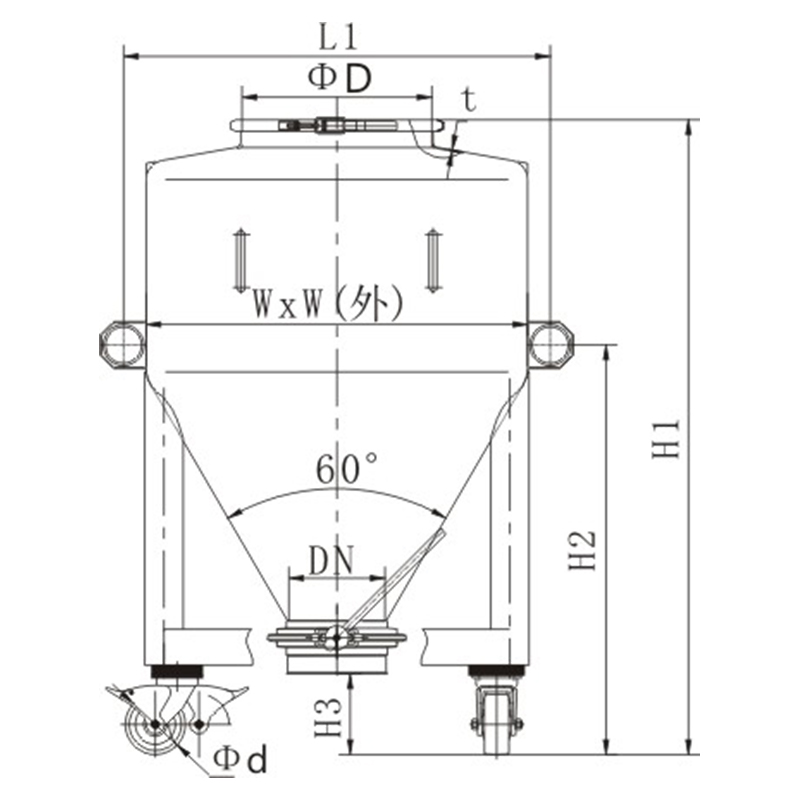

| Mixed IBC Silo | |||||||||

| Specification (mm) | |||||||||

| Model | Volume(L) | H1 | H2 | H3 | L1 | ΦD | φd | W1 | DN |

| LDF200M | 200 | 946 | 700 | 100 | 770 | 400 | 100 | 694 | 200 |

| LDF300M | 300 | 1258 | 800 | 180 | 788 | 400 | 125 | 694 | 200 |

| LDF400M | 400 | 1318 | 850 | 166 | 888 | 400 | 125 | 794 | 200 |

| LDF600M | 600 | 1475 | 950 | 163 | 988 | 500 | 125 | 894 | 200 |

| LDF800M | 800 | 1508 | 1000 | 141 | 1088 | 500 | 125 | 944 | 200 |

| LDF1000M | 1000 | 1672 | 1050 | 125 | 1210 | 500 | 125 | 1094 | 250 |