Products Description

Brief Introduction

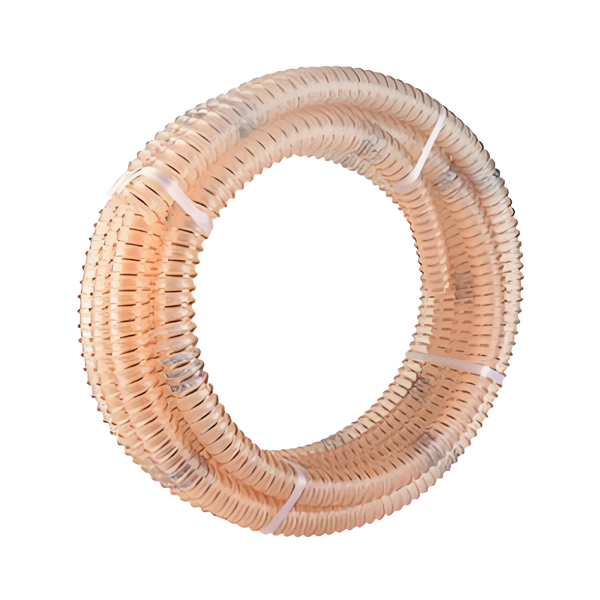

PUR Suction Hose (Polyurethane Suction Hose) is an advanced industrial-grade flexible hose manufactured from high-performance polyurethane material. Specifically engineered for demanding suction and material handling applications, this hose combines exceptional durability with remarkable flexibility. The unique molecular structure of polyurethane provides an ideal balance between mechanical strength and elasticity, making it suitable for various industrial vacuum systems and pneumatic conveying equipment.

These hoses typically feature a smooth inner bore for optimal flow characteristics and are reinforced with high-tensile steel wire or textile spirals to prevent collapse under vacuum conditions. Available in both standard and anti-static versions, PUR suction hoses maintain their flexibility across a wide temperature range from -40°C to +90°C, with some specialized grades capable of withstanding temperatures up to 125°C.

Features

1. Exceptional Abrasion Resistance

• Outstanding wear resistance, 7-10 times more durable than PVC hoses

• Maintains integrity when handling abrasive materials like wood chips, granules

• Prolonged service life in high-wear applications

2. Superior Mechanical Properties

• Excellent flexibility and kink resistance

• High tensile strength with good elongation characteristics

• Withstands repeated bending and flexing without damage

3. Comprehensive Material Compatibility

• Resistant to oils, greases, and most chemicals

• Handles a wide range of industrial materials and compounds

• Suitable for food-grade applications with proper certification

4. Optimal Performance Features

• Smooth inner surface minimizes flow resistance

• Lightweight construction reduces handling fatigue

• Transparent versions available for visual monitoring

5. Environmental and Safety Benefits

• ROHS compliant and environmentally friendly

• Anti-static options for explosive environments

• Low temperature flexibility maintains performance in cold conditions

Application Scenarioses

Woodworking Industry: Dust extraction from sanders, saws, and planners

Manufacturing Facilities: Industrial vacuum systems and central cleaning

Mining Operations: Dust collection and material transfer applications

Food Processing: Grain handling and ingredient transfer systems

Construction Industry: Concrete dust extraction and debris removal