Products Description

Brief Introduction

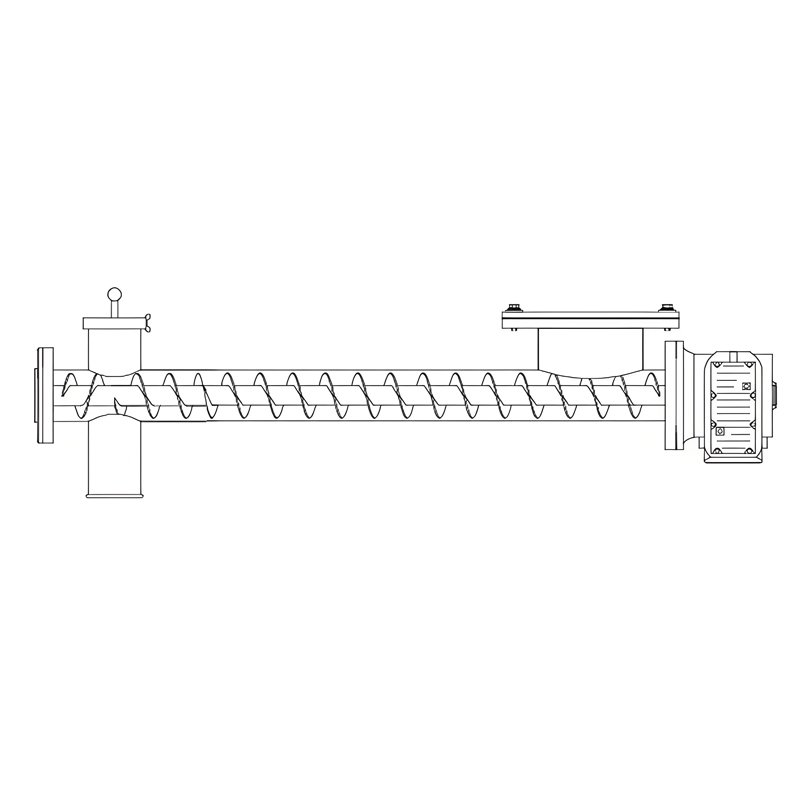

The screw conveyor is made of 304 or 316 stainless steel with a polished finish, ensuring cleanliness and hygiene.

It is rust-resistant and features excellent sealing performance, which can prevent contamination of the conveyed materials and the environment.

With good wear resistance and corrosion resistance, it can convey powder, granular and small lumpy materials at 200℃.

In addition, the lower end of the feed inlet of the stainless steel screw conveyor is equipped with a discharge valve, and the screw can reverse to discharge materials, making discharging and cleaning very convenient.

It is suitable for horizontal or inclined conveying of powdery, granular and small lumpy materials, and is applied in fields such as food, medicine, and sewage/sludge treatment.

Features

1. Excellent Sealing Performance

Fully enclosed structure prevents dust leakage

Protects materials from environmental contamination

Suitable for conveying hazardous materials

2. Flexible Layout Options

Supports horizontal, inclined, and vertical installation

Allows multiple feeding and discharge points

Adapts to complex spatial layouts

3. Stable Conveying Performance

Continuous and uniform material conveying

Precisely controllable conveying capacity

Resistant to clogging

4. Simple Maintenance Requirements

Simple structure with low failure rate

Few wear parts and low maintenance costs

Modular design facilitates inspection and repair

5. Wide Application Range

Adapts to various material characteristics

High-temperature and corrosion-resistant designs available

Explosion-proof models optional

Application Scenarioses

Grain Processing: Conveying of grains, flour, and feed

Chemical Industry: Transportation of plastic pellets, fertilizers, and raw materials

Building Materials: Cement, fly ash, and dry mortar

Environmental Engineering: Sludge conveying and waste treatment

Metallurgical Industry: Transportation of mineral powders and metal powders