Products Description

Brief Introduction

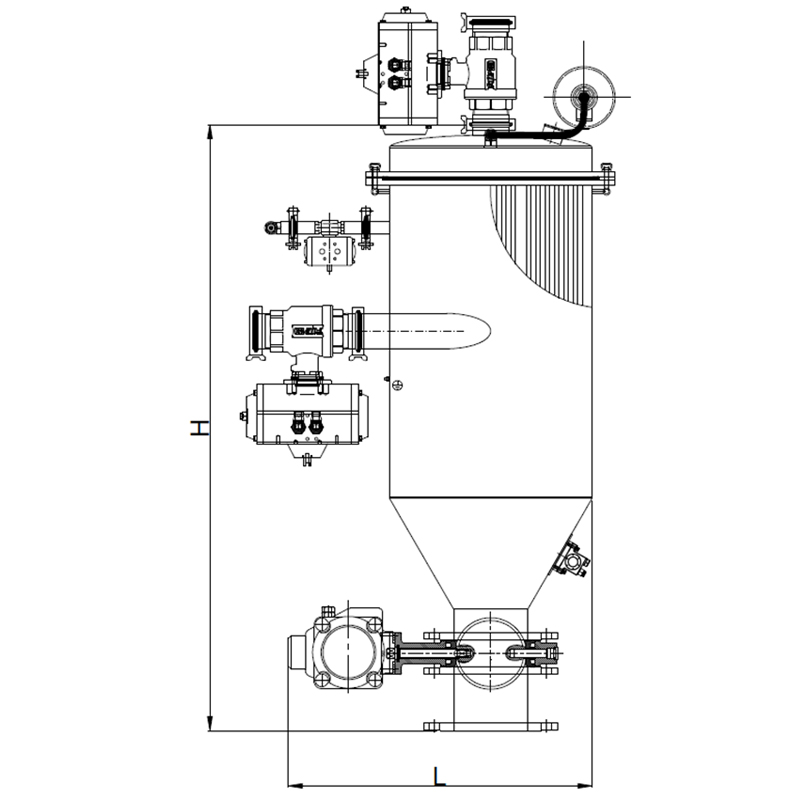

In the pharmaceutical industry, materials containing ethanol are often conveyed. Due to ethanol’s low ignition point, even a slight oversight during the material conveying process can pose an explosion risk, which poses a significant threat to the surrounding environment and personal safety. In such cases, it is essential to use explosion-proof vacuum conveying equipment—vacuum conveyors equipped with a nitrogen protection device.

Features

The entire system uses nitrogen as both the power source and protective gas.

A conveying process where air serves as the power source, and nitrogen is only used as the protective gas.

No electrical energy or mechanical energy is required; the entire system can be controlled and operated solely by compressed air.

Automatic control: The material suction and discharge time can be set arbitrarily within 0–30 seconds, featuring simple and convenient operation.

Complies with GMP standards and meets CIP requirements.

Compact size, light weight, and simple, quick installation.

No vibration and low noise.

Dust-free operation, with fast and convenient cleaning and material changeover.

One machine can be used alternately on multiple sets of equipment; no warm-up or standby time is needed, and maintenance costs are low.

No electrical energy or other energy sources are required; no heat is generated during operation, ensuring safe and explosion-proof performance.

Parameters

MODEL | GJFB-180 | GJFB-250 | GJFB-320 | GJFB-430 | GJFB-560 | |

Compressed Air | Pressure | 0.6Mpa | 0.6Mpa | 0.6Mpa | 0.6Mpa | 0.6Mpa |

Gas Consumption | 0.7M3/min | 1.5M3/min | 1.8M3/min | 2.7M3/min | 3.6M3/min | |

Transport Capacity | 0.1-0.5T/h | 0.3-0.8T/h | 0.5-1.2T/h | 1.0-3.0T/h | 2.0-5.0T/h | |

Precision Filter | Star-shaped polyester fiber filter Ti07-1/2, Titanium alloy sintered filter element, Sintered filter rod PE-HD, Stainless steel filter rod | |||||

Filter Area | 0.33M2 | 0.33M2 | 0.99M2 | 2M2 | 2.3M2 | |

Suction Port | φ38/φ51 | φ38/φ51 | Φ51/φ76 | Φ76/φ102 | Φ102/φ133 | |

Blanking Port | DN125/DN150 | DN125/DN150 | DN150/DN200 | DN200/DN250 | DN250/DN300 | |

Bin Volume | 6L | 12L | 24L | 48L | 96L | |

Specification | L350*W250*H900 | L400*W300*H1050 | L450*W400*H1100 | L500*W450*H1360 | L650*W580*H1560 | |

Control System | PLC Control (Exd IIB T4Gb) or Full-pneumatic Control System | |||||